Our Technology

Operating Principle – Water Circulates through a Heat Exchanger in the Subsurface

To extract the inexhaustible heat stored in solid rock for electricity and heat production, water must be able to circulate in the solid rock as if through an heater (heat exchanger). Normally, the naturally occurring water at the required depth would be for the economic operation of a power plant. To achieve this, a deep well is drilled through which large quantities of water are pumped at pressure into the underground. This proicess enlarges existing cracks and the spreading cracks create a large heater exchanger at depth. The target depth usually varies between 3,000 (9,842.7 ft) and 5,000 metres (16,404.5). A second well completes the system. During operation, cold water is pumped through the first well into the subsurface, where it flows through the cracks, heats up and finally rises to the surface through the second well

The hot water can be used to generate electricity and/or for heating.

Significant Developments Due to Early Pilot Plants

For several decades, research has been conducted worldwide on the development of artificial deep geothermal systems. This has resulted in several pilot plants in different regions of the world.

The Deep Heat Mining project in Basel was the first pilot plant to be constructed in Switzerland. The work provided valuable information for the understanding and conception of such geothermal projects in Switzerland. The comprehensive analysis of the data obtained showed various factors that significantly influenced the development of the induced seismicity, which ultimately led to the project being abandoned. However, the overall evaluation also showed that a huge reservoir was successfully created at depth in Basel by thousands of induced microearthquakes.

Important Insights Gained

A key insight from the projects to date is that the magnitude of the induced seismicity depends on the size of the artificially created fracture surface (reservoir area) (source of graphic on the right: Serianex, 2009).

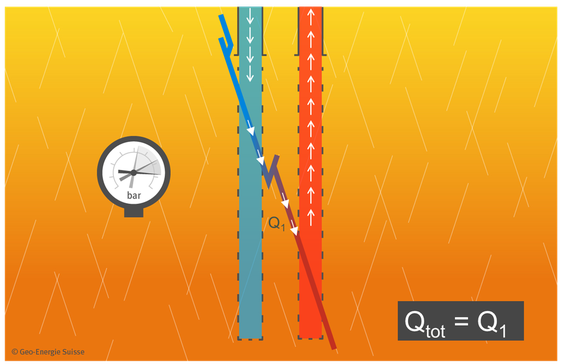

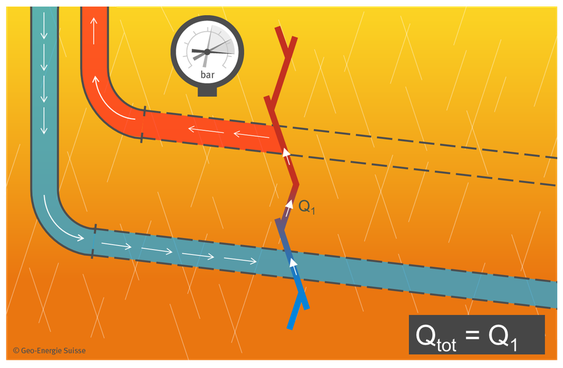

The evaluations have also shown that in the deep subsurface, forces prevail that create vertical cracks during stimulation. In order to be able to accurately drill into these crack surfaces and use them as an heat exchanger during the operating phase, they should not be accessed by vertical drilling (as has been attempted so far) but by horizontal drilling.

The New Innovative Multi-Stage Stimulation System

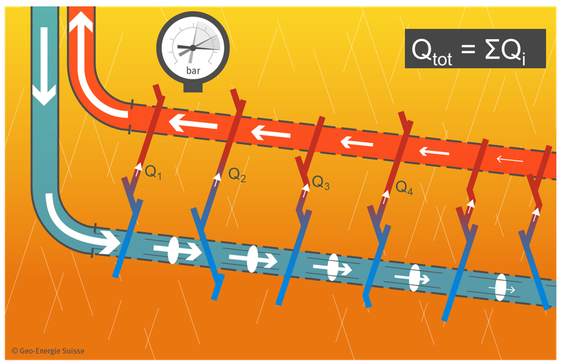

Based on the extensive knowledge gained from various pilot projects, Geo-Energie Suisse AG has developed an innovative multi-stage stimulation system. The multi-stage stimulation system is designed to optimise the efficiency of the reservoir and the profitability of the power plant whilst to minimising the risk of induced seismicity on the other. This is achieved by fully exploiting the temperature level at the desired target depth and by better control of the formation and flow through the reservoir (heat exchanger).

Existing Horizontal Drilling Technology

The drilling and well bore equipment for increasing permeability using a multi-stage stimulation system is based on the extensive experience and impressive learning curve of the oil and gas industry. This mainly concerns the development of unconventional deposits for fossil hydrocarbons. Several potential suppliers of such equipment have already been evaluated by Geo-Energie Suisse AG's internal specialists.

Drilling Project Ready for Execution – Our Experienced Partners

The concept of the multi-stage stimulation system forms the basis on which Geo-Energie Suisse AG has developed a drilling project ready for execution with the associated technical specifications for the drilling rig. To this end, Geo-Energie Suisse AG worked together with Rohöl-Aufsuchungs-Aktiengesellschaft (RAG Energy Drilling), the oldest existing company in the field of oil and gas exploration in Austria.

Basic Principle of the Multi-Stage Stimulation System

The basic principle of the new system consists of combining a step-by-step approach with continuous seismic and hydraulic monitoring and re-evaluation of the project as construction progresses. This means that the project work can be adapted to new circumstances at any time and even stopped if necessary.