Horizon 2020

ThermoDrill

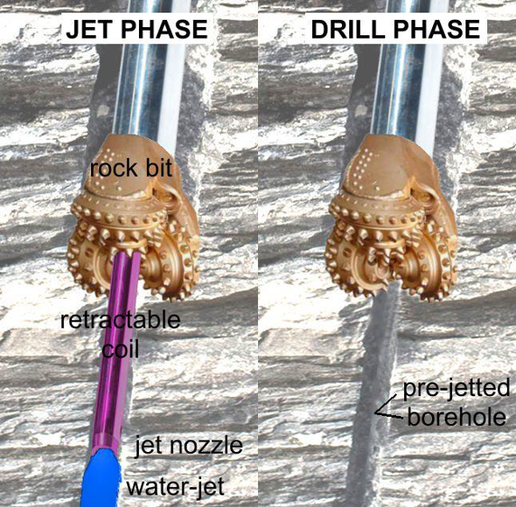

As part of the EU's Horizon 2020 programme, Geo-Energie Suisse AG is working with six European companies and two universities on the ThermoDrill project. The aim is to significantly accelerate drilling progress in crystalline rock by developing a new innovative drilling system, which would significantly reduce drilling costs. These represent one of the main cost factors of the projects planned by Geo-Energie Suisse. The project period extends from September 2015 to the end of August 2019.

ThermoDrill project: significant reduction in drilling costs through the development of an innovative drilling system.

DESTRESS

‘DESTRESS’ (Demonstration of soft stimulation treatments of geothermal reservoirs) is another international research project under Horizon 2020 in which Geo-Energie Suisse AG is involved. Here, Geo-Energie Suisse is working with 16 partners from research and industry from March 2016 to February 2020 to optimise stimulation measures for the development of geothermal reservoirs. The key factors here are maximising the efficiency of the reservoir and the sustainability of the system created (flow heater), while minimising the environmental impact, such as induced seismicity.

The partners in the DESTRESS consortium are:

- Helmholtz Centre Potsdam (GFZ), Germany

- Energie Baden-Württemberg AG (EnBW), Germany

- és-Géothermie (ESG), France

- University of Glasgow, United Kingdom

- Geo-Energie Suisse AG, Switzerland

- TNO, the Netherlands

- Swiss Federal Institute of Technology Zurich (ETH), Switzerland

- Geothermie Neubrandenburg GmbH (GTN), Germany

- Geoterma UAB, Lithuania

- Université de Strasbourg, France

- Delft University of Technology (TU Delft), the Netherlands

- NexGeo Incorporated, South Korea

- Seoul National University (SNU), South Korea

- Korea Institute of Civil Engineering and Building Technology (KICT), South Korea

- ECW Geomanagement BV (ECW), Netherlands

- Trias Westland B.V., Netherlands

DESTRESS Work – development of suitable packers as a milestone

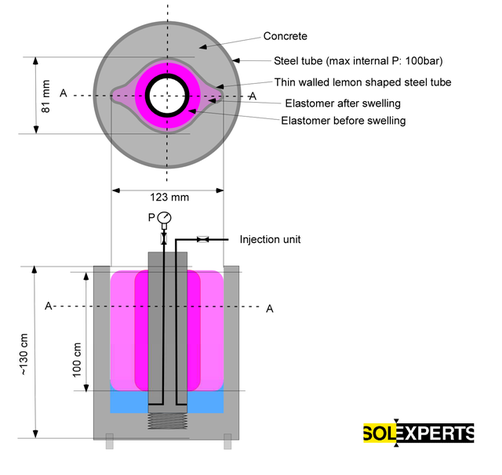

The work of Geo-Energie Suisse AG is mainly carried out for the development and testing of the borehole equipment for the multi-stage stimulation technique and the Haute-Sorne project. In 2016 and 2017, the packers required for multi-stage stimulation were tested by the company Solexperts (see figures).

At depth, boreholes take on the shape of a lemon – which is why new packers need to be developed for sealing

In the deep subsurface, different forces act on a borehole in different directions. As a result, a deep borehole does not take on a circular shape, but rather a more or less pronounced lemon-shaped one. The aim is now to further develop the packers used in the hydrocarbon industry so that they can completely seal off a certain section of the borehole hydraulically (Fig. 2) despite the non-uniform borehole (Fig. 1). This is a necessary prerequisite for the successful application of the multi-stage stimulation system.

Opposite:

Scan of the deep well in Basel at a depth of almost 4400 m. On the left, a three-dimensional depth section over 5 m in length can be seen. The darker areas correspond to the lemon-shaped ends. The figure on the right shows a view from above into the borehole; the deviation from the circular shape is clearly visible.

Packer tests in the laboratory – 2 packers showed promise in the tests

A total of four packers from different manufacturers were tested. Two of the packers proved to be unusable and will not be examined in more detail. The tests for the other two packers were positive. The necessary improvements are now being made to adapt the packers to the requirements of multi-stage stimulation

The tests of various packers in the laboratory and the subsequent adaptation to the specific needs of Geo-Energie Suisse makes it possible to significantly reduce the operational risk during subsequent use in the well.

Opposite:

Overview and cross-section of the packer test set-up. The packers are inserted into a lemon-shaped pipe. The dark purple area shows the original position. After swelling (light purple), the packer should completely seal the corresponding pipe section so that the water injected below can no longer flow past the packer. The aim is to use the packers in the borehole to isolate individual selected sections from each other and to stimulate them individually by means of water injections (multi-stage stimulation system).